News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

News center

Letter of notification of the new location of Ji kerr

Welcome new and old customers, friends from all walks of life to visit and guide the work, inconvenience, please understand!

2023-02-17

Ji kerr 2023 Spring Festival holiday notice

2022-12-26

2022-04-18

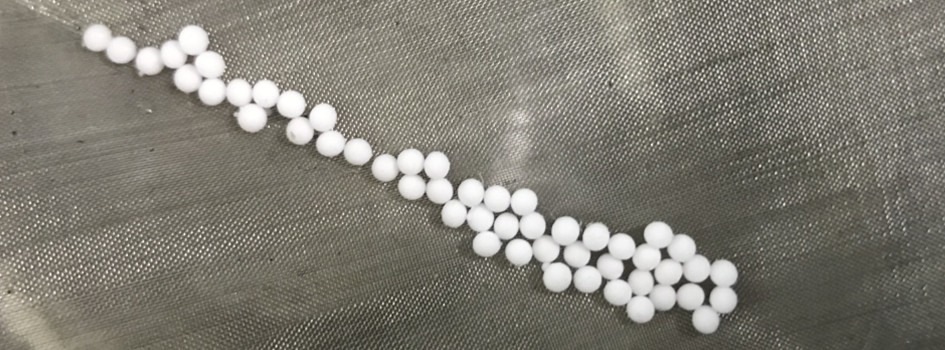

Liquid nitrogen drops frozen beads technology and automation system solutions

Liquid reagents require cold chain transportation and low temperature preservation, high transportation and preservation costs, harsh conditions, unstable performance, and short shelf life. The freeze-dried beads have the following advantages, and with the reduction of production costs brought about by mass production in the future, it will certainly help the explosive growth of rapid IVD diagnosis.

2022-04-16

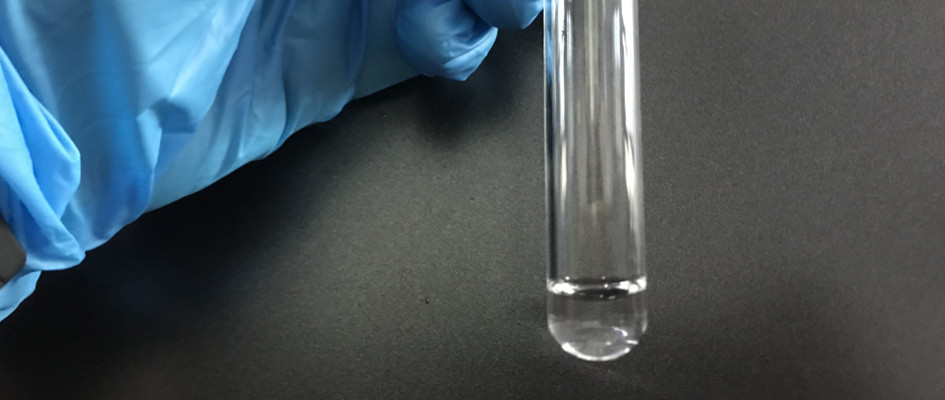

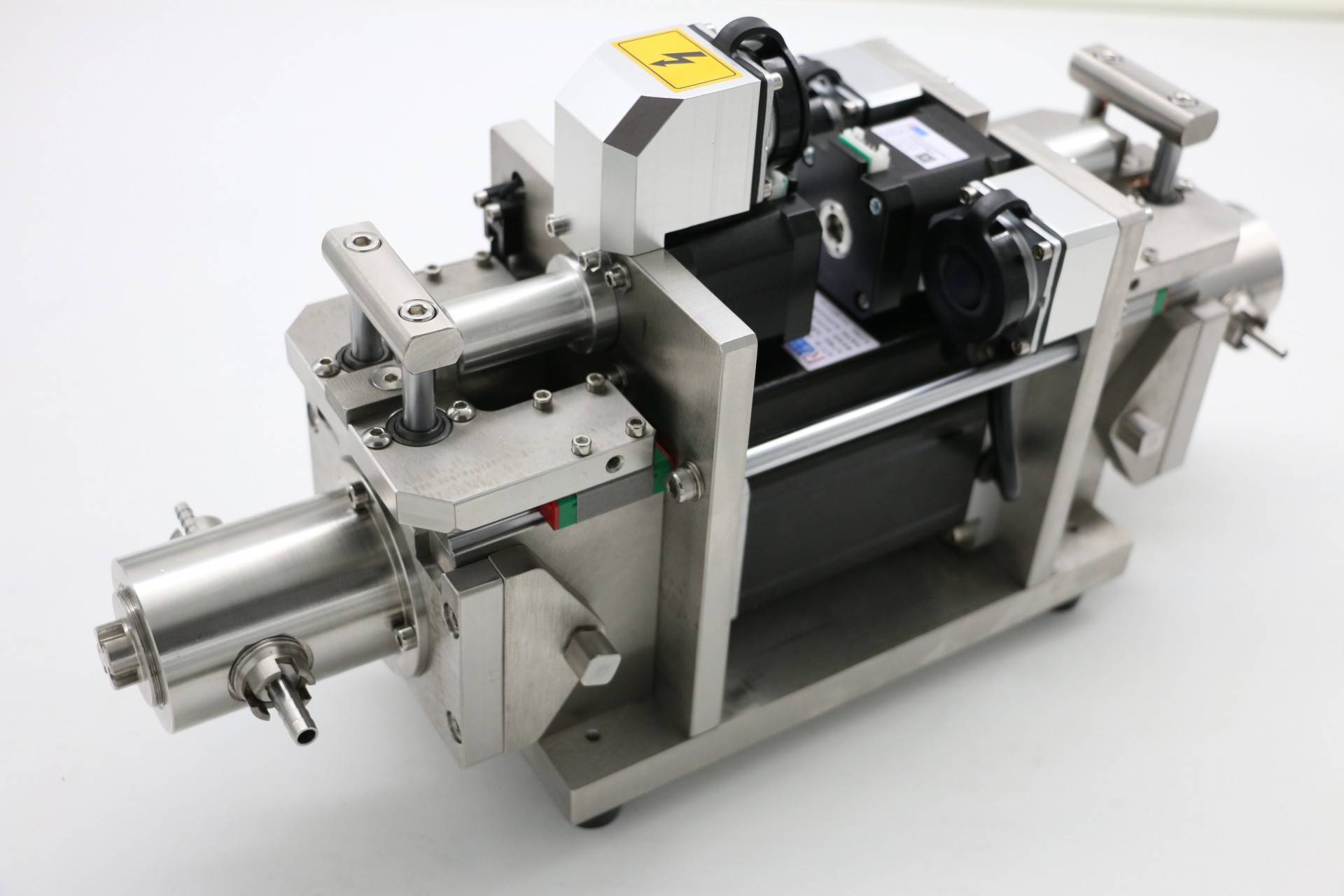

The application of Ji kerr ceramic metering pump in COD precast reagent industry

2022-04-15

Ji kerr ceramic injection pump in the lithium battery industry injection application

2022-04-14

5G ultra-thin VC enters the process transformation and the rise of automation

the contradiction between the performance of 5G smartphones and high power consumption heating may be intensified, or promote the demand for heat dissipation products.

2022-04-13

This is the difference between VC soaking plate and heat pipe application

and improve the efficiency of the radiator. The inner wall of the heat pipe is a layer of capillary structure, which is filled with liquid and vacuumed.

Installed in the heat source end we call the evaporation end, when the heat is released, the evaporation end of the internal liquid gasification, transferred to the other end of the lower pressure condensing end,

the condensing end is cold and condensed into water.

2022-04-12