News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

trade news

Home > News center > trade news

News center > trade news

This is the difference between VC soaking plate and heat pipe application

Date:2022-04-12 browse:524

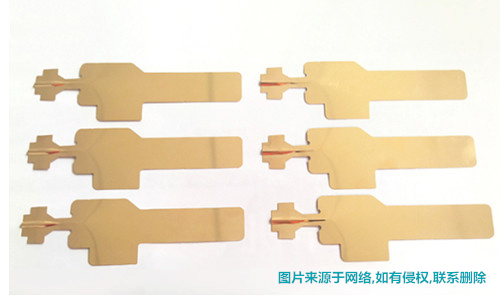

VC soaking plate is a vacuum chamber with a fine structure on the inner wall, usually made of copper.

The function is to reduce the diffusion thermal resistance between the heat source and the radiator,

and improve the efficiency of the radiator. The inner wall of the heat pipe is a layer of capillary structure,

which is filled with liquid and vacuumed. Installed in the heat source end we call the evaporation end, when the heat is released,

the evaporation end of the internal liquid gasification, transferred to the other end of the lower pressure condensing end,

the condensing end is cold and condensed into water.

The VC soaking plate uses a traditional two-piece design.

Although studies and practical applications have shown that the performance of the VC radiator is 20-30% higher than that of the heat pipe,

the cost of the two-piece design is about the same as that of the multi-tube heat pipe application. However,

based on some heat dissipation advantages on the application, two-piece VC is gradually increasing in application.

The two-piece design is easier to manufacture and can be made into almost any shape. The flexibility of its structural form is a major advantage.

The single-chip integrated VC costs less than the two-chip VC and maintains the same thermal performance characteristics while adding some unique features (such as U-bend).

Like heat pipes, single-chip VC, like heat pipes, is in direct contact with the heat source and has multi-directional heat flow. However,

their production costs are lower because their production process is simple, requires fewer production tools, and less unnecessary welding work.

The greater total power and power density requirements require the use of multiple heat pipes to address the challenges posed by heat dissipation.

Radiator for small, high-performance desktop computers. A copper substrate is used between the heat source and the heat pipe,

which is common in heat pipe applications (indirect contact). As CPU heat continued to increase in the product, heat dissipation encountered problems,

but the design did not want to fundamentally redesign the heat dissipation scheme. VC replaces the copper substrate,

dissipating heat more evenly over the heat source and delivering it more efficiently to the heat pipe.

This is a typical case of the mixed use of two heat dissipation components.