News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

Company news

Home > News center > Company news

News center > Company news

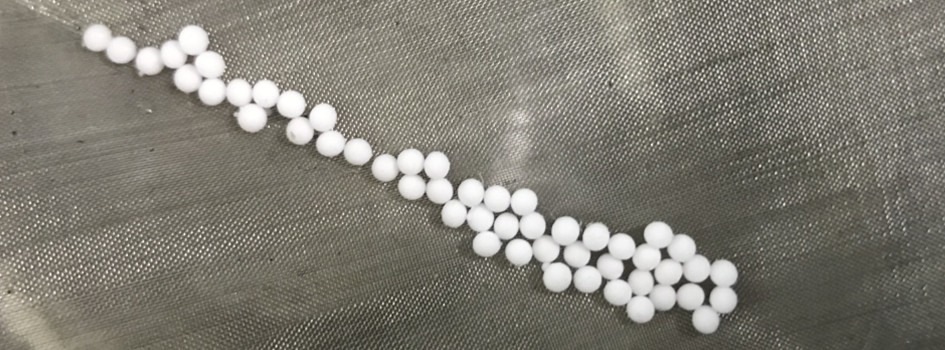

Liquid nitrogen drops frozen beads technology and automation system solutions

Date:2022-04-16 browse:803

"IVD" full name "invitrodiagnosticproducts", Chinese translation for in vitro diagnostic products.

As one of the hot emerging technologies in the global IVD diagnostic market, liquid nitrogen freeze-dried beads have developed rapidly in the past two years.

From overseas IVD exhibitions and domestic IVD exhibitions, from reagent manufacturers to instrument manufacturers,

attention to freeze-dried bead technology continues to rise.

As overseas multinational companies accelerate the promotion of freeze-dried bead technology and begin to lay out mass production,

in the near future, freeze-dried bead will become the market mainstream in the field of IVD.

Liquid reagents require cold chain transportation and low temperature preservation, high transportation and preservation costs,

harsh conditions, unstable performance, and short shelf life. The freeze-dried beads have the following advantages,

and with the reduction of production costs brought about by mass production in the future, it will certainly help the explosive growth of rapid IVD diagnosis.

IVD industry reagent preservation is an important problem in the medical industry.

Biological reagents are biologically active substances and are particularly sensitive to temperature.

The chemical properties are relatively active and easy to react with each other. Due to the above characteristics,

the storage time of biological reagents is generally relatively short and needs to be frozen, otherwise it will quickly deteriorate. In addition,

many biological reagents (such as nucleic acid detection reagents) require storage at room temperature,

which requires that biological reagents cannot be stored in liquid form and need to be dehydrated. Reagent dehydration methods are generally:

1. Glue and dry.

2. Liquid nitrogen freeze-dried bead point pellet technology.

Dispensing drying adopts the technology of heating drying to dry the water in the reagent through the method of vacuum high temperature heating.

But this simple method of dehydration has major disadvantages. High temperature may affect enzymes and proteins, and it is relatively difficult to redissolve.

The freeze-dried bead technology uses the freeze-drying technology to dehydrate the reagent.

The freeze-dried bead technology can maintain the activity of enzymes/proteins to the maximum extent,

and the freeze-dried bead has a loose network structure and rapid redissolution. Freeze-dried beads technology can transform unstable chemical reagents into high quality,

stable and quantitative freeze-dried beads.

Liquid nitrogen freeze-dried bead point pellet technology is to drop reagent liquid in a device stored with liquid nitrogen,

so that it is solidified into pellets in a very short time at low temperatures. Liquid nitrogen, liquid nitrogen, is inert (does not react with other substances),

colorless, odorless, non-corrosive, non-flammable, very low temperature liquid, its excellent characteristics and reasonable price,

determines that liquid nitrogen is the ideal low temperature freezing medium. After the liquid drops into liquid nitrogen and forms a ball,

it can be freeze-dried using a common freeze-drying machine with a controllable cost, in which the pressure needs to be controlled. At this stage,

the main technical difficulty for liquid nitrogen freeze-dried bead point pellet technology lies in the point liquid:

1. Microdot liquid: Liquid nitrogen freeze-dried beads generally require microdot liquid, the common amount of liquid from 1 microliter (1 mg) to 10 microliters.

The ordinary pump that people are familiar with is difficult to continuously stabilize the point liquid in such a small range and ensure consistency.

2. Precision point liquid: freeze-dried beads have high requirements for the accuracy and shape of the point liquid. In laboratory operation,

due to the problem of manual consistency and simple equipment, it is often difficult to control the accuracy and consistency.

If the ordinary pump is used, the controllability and accuracy of the pump are not good when the trace liquid is pointed,

which can easily cause the shape and size of the ball to be different, the shape of the ball is not good,

or the ball explodes into multiple microspheres when it falls to the surface of liquid nitrogen. When the amount of liquid is small,

it can not form a round ball with the same shape, and the amount of freeze-dried beads is difficult to dissolve.

If the shape of the product's freeze-dried beads is inconsistent and the size is different, it will affect the subsequent testing process and test results.

In order to solve the above problem of trace fluid point fluid, the technical team of Dongguan Jikel Automation Technology Co.,

Ltd. has focused on the research and development of trace fluid control system since 2019, focusing on the micro level and nano level of trace fluid point fluid,

based on the micro fluid pump technology, has launched a suitable for laboratory/small batch production.

And mass production of a number of liquid nitrogen freeze-dried bead point pellet system.

The liquid nitrogen freeze-dried bead system uses precision micro-ceramic pump technology with the point liquid amount as low as 1 microliter.

The components in contact with the pharmaceutical liquid are pharmaceutical grade sapphire grade ceramics, Teflon and 316 stainless steel materials,

which will not react with the pharmaceutical liquid, so as to ensure the activity, stability and will not be polluted.

The amount of liquid and the speed of liquid point can be quickly adjusted, plus the company can customize a variety of special needles,

can achieve the rate of liquid point, liquid point does not hang drops, point to liquid nitrogen does not burst beads, do not bead,

freeze-dried bead ball round effect is good, uniform shape and volume, the size is consistent,

effectively solve the biochemical customers commonly faced with freeze-dried bead balls easy to hang or explode, inaccurate, poor ball effect,

The problem of poor consistency. Jickel has a variety of specifications of micro ceramic pumps to choose from,

as low as 1 microliter to dozens of microliters above the point liquid volume range can achieve high precision point liquid, point liquid accuracy of up to 0.5%,

can meet the customer's various point liquid requirements.