News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

News center

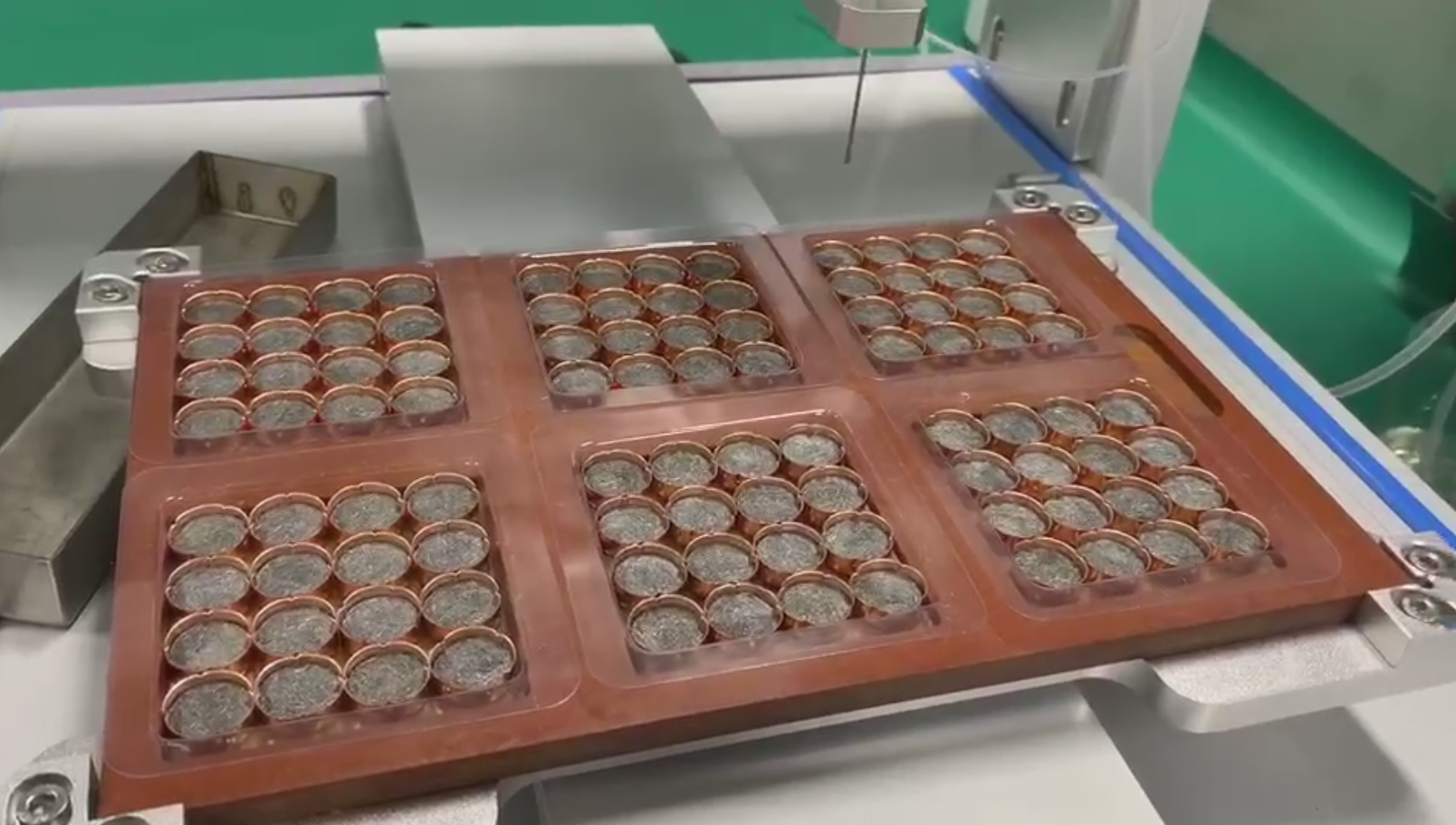

Ji kerr precision ceramic metering pump is applied in AF anti-fingerprint liquid spot

plastics, mechanical metal parts, auto parts and other fields, has been widely used.

AF vacuum coated pill has the following characteristics:

2022-04-11

Among them, ceramic variable pump, multi-head ceramic variable pump, non-pulsating constant flow pump, micro ceramic piston pump and so on

Ten years of hard work has made due contributions to promoting the localization of precision ceramic metering pumps and improving the overall level of domestic liquid injection equipment.

"Before the establishment of Ji kerr, domestic lithium battery companies mainly used Canada's Haiba pump and the United States IVEK ceramic pump,

in 2013 Ji kerr successfully launched a single-head ceramic injection pump, and with excellent performance and price, batch localization, to replace,

to promote the rapid localization of liquid injection equipment, farewell to foreign liquid injection pump neck."

2022-04-02

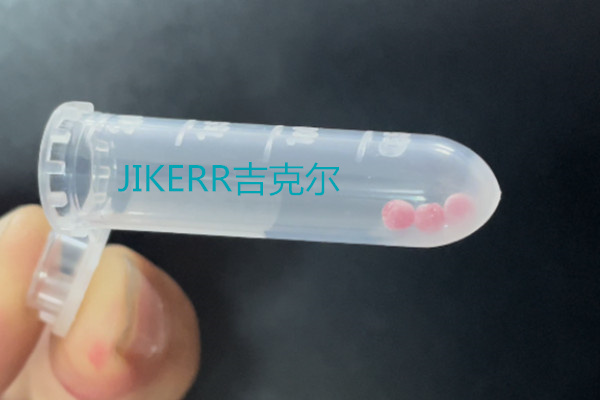

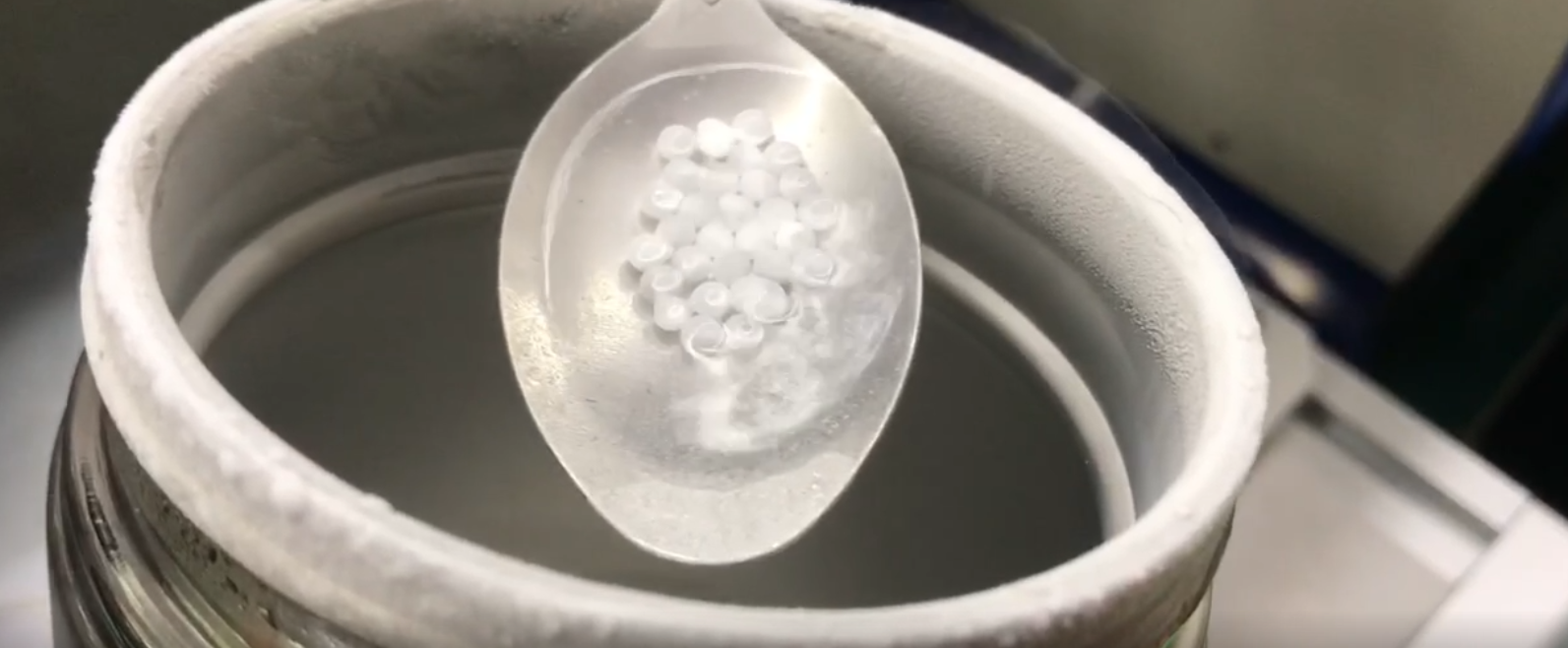

Freeze-dried balls, also known as freeze-dried beads, liquid nitrogen point balls

is the mixed active biological reagents through the Ji kerr liquid nitrogen point liquid freeze bead machine point liquid into liquid nitrogen to freeze into the size and weight of the ball required,

and freeze-dried machine vacuum freeze drying processing, to get smooth sphere-freeze-dried ball. The freeze-dried balls of collagen and polypeptide are processed by freeze-dried machines.

2022-04-01

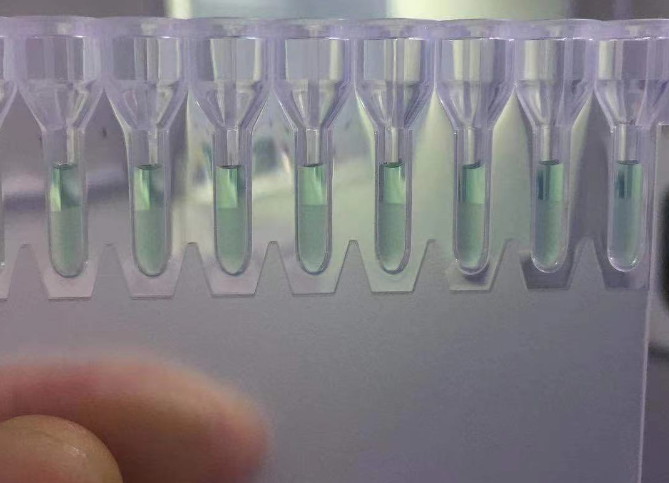

Application of Ji kerr ceramic metering pump in IVD in vitro diagnosis industry

especially the measurement accuracy of the milligram level. In order to help domestic IVD enterprises to achieve the localization of key components replacement,

Ji kerr for the IVD industry on liquid path, fluid precision metering transportation, liquid point, liquid injection and packaging related needs,

integration of the whole range of products (including: Micro-ceramic liquid injection pump, micro-ceramic metering valve) launched micro-pump application solutions for the IVD industry,

in order to better meet customer needs and contribute to the overall development of the IVD industry.

2022-04-01

What is the difference between zirconia ceramics and ordinary ceramics?

75 porcelain, 85 porcelain, 95 porcelain, 96 porcelain, 99 porcelain and so on; Can also make substrate, substrate, porcelain ring, porcelain rod,

porcelain seat, tube seat, circuit shell, spark plug, wear-resistant valve, automotive circuit wiring insulation ceramics, etc., zirconia ceramics and ordinary ceramics difference?

2022-04-01

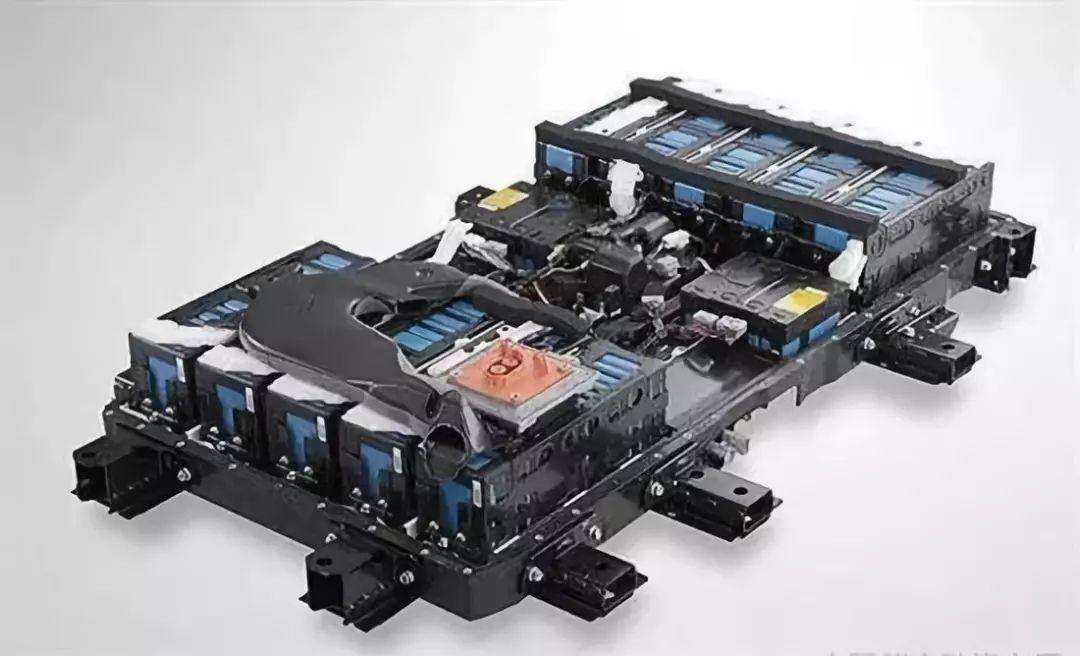

To interpret the recycling and reuse of lithium-ion batteries for new energy vehicles

At the same time, the industry estimates that in 2015, the cumulative scrap of new energy vehicle batteries is about 20-40,000 tons.

The recycling of lithium-ion batteries for new energy vehicles has become a problem that cannot be ignored.

2022-03-28

Quickly understand the difference between Class I, Class II and Class III medical device licenses

2022-03-23

Liquid nitrogen freeze-dried microspheres

Microsphere preparation has the following characteristics:

1. Targeting;

2. Slow release and long-term performance;

3. Embolism;

4. Cover up the bad smell and taste of the drug;

5. Improve drug stability and reduce gastric irritation;

6. The liquid drug becomes solid.

There are three common methods for preparing microspheres: emulsification and dispersion, condensation and polymerization. Different preparation methods can be selected according to different particle size, drug release properties and clinical administration routes of microspheres.

2022-03-18