News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

Company news

Home > News center > Company news

News center > Company news

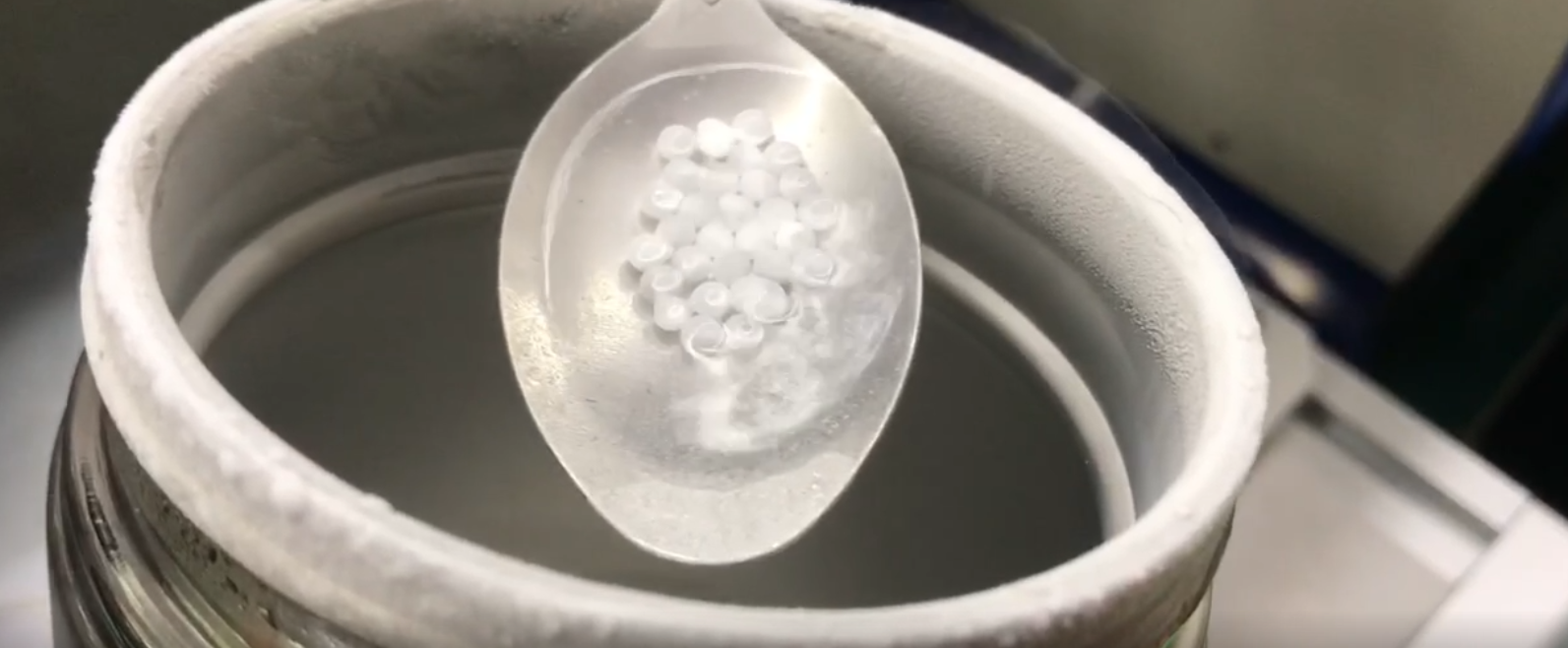

Liquid nitrogen freeze-dried microspheres

Date:2022-03-18 browse:490

Liquid nitrogen frozen microspheres refer to tiny spherical entities formed by drug dispersion or adsorption in the polymer matrix,

and their particle size is generally between 1-250 μm.

Microsphere preparation has the following characteristics:

1. Targeting;

2. Slow release and long-term performance;

3. Embolism;

4. Cover up the bad smell and taste of the drug;

5. Improve drug stability and reduce gastric irritation;

6. The liquid drug becomes solid.

There are three common methods for preparing microspheres: emulsification and dispersion, condensation and polymerization.

Different preparation methods can be selected according to different particle size, drug release properties and clinical administration routes of microspheres.

The main disadvantage of microsphere preparation is its limited drug load. The production process and quality standards are more complicated.

Biological reagents (such as nucleic acid detection reagents) are required to be stored at room temperature,

which requires that biological reagents cannot be stored in liquid form and need to be dehydrated. Reagent dehydration methods are generally:

1. Dispensing drying.

2. Liquid nitrogen freeze-dried ball technology (freeze-dried bead technology).

Dispensing drying adopts the technology of heating drying to dry the water in the reagent through the method of vacuum high temperature heating.

High temperature may affect enzymes and proteins, and it is relatively difficult to redissolve.

Freeze-dried microsphere technology uses freeze-drying technology to dehydrate reagents.

The freeze-dried microsphere technology can maintain the activity of enzymes/proteins to the maximum extent,

and the freeze-dried microsphere has a loose network structure and rapid redissolution.

Freeze-dried ball technology can convert unstable chemical reagents at room temperature into high-quality,

stable, quantitative freeze-dried balls that can be stored for a long time, at room temperature, and can also be stored at 2~8℃.