News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

Company news

Home > News center > Company news

News center > Company news

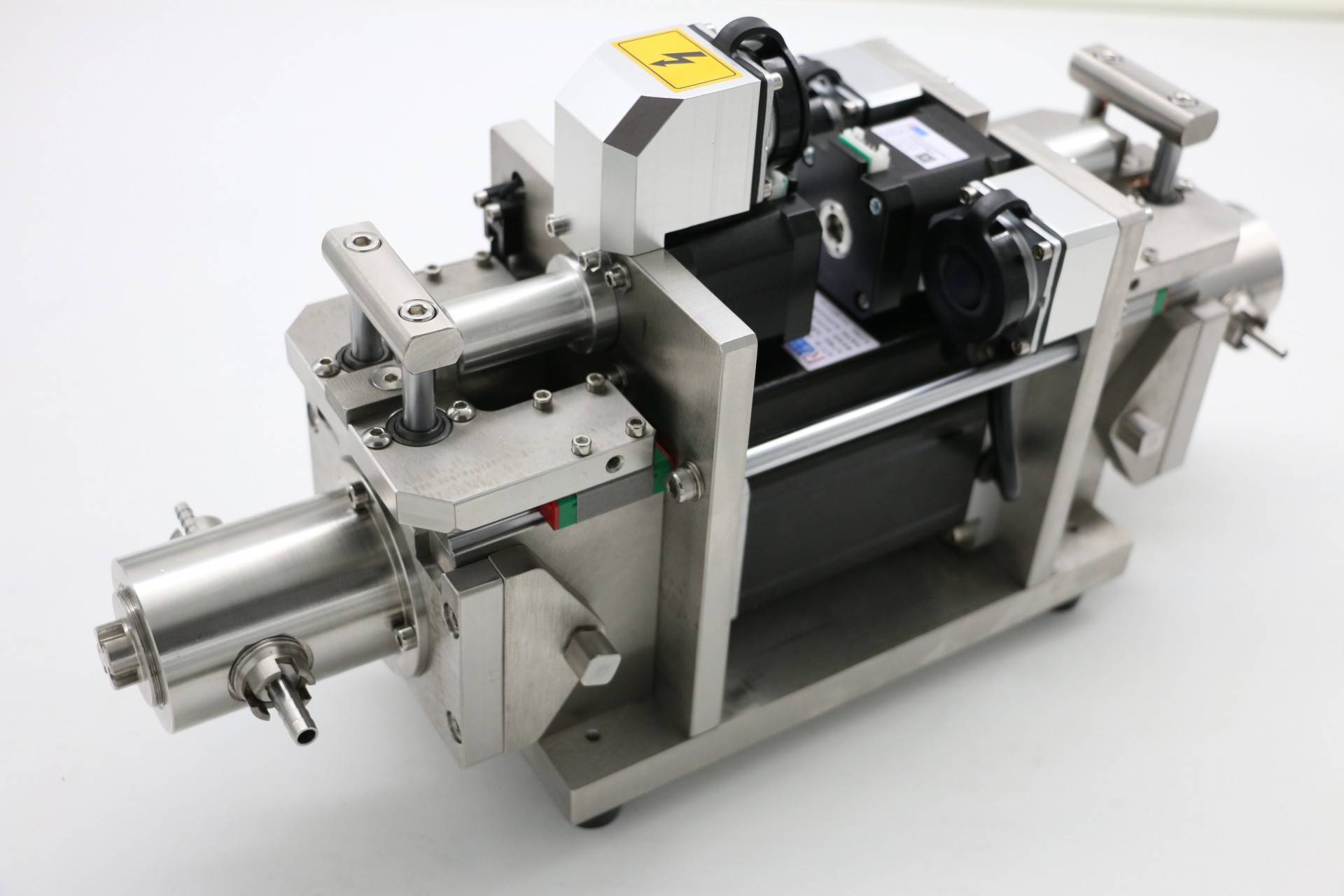

Ji kerr ceramic injection pump in the lithium battery industry injection application

Date:2022-04-14 browse:724

The role of the electrolyte in the lithium battery cell is to conduct ions between the positive and negative electrodes, acting as a medium for charging and discharging,

just like human blood. It is very important to let the electrolyte be injected into the cell with standard accuracy and infiltrate the positive and negative electrode pieces.

Because the amount of liquid injected in some liquid injection processes is a very close process, if the amount of electrolyte injection is more or less,

it will directly affect the performance of the battery.

The formula is simply described as follows:

Liquid injection amount = battery capacity x (cobalt lithium, iron lithium, manganese lithium) material system

Volume x electrolyte density = theoretical dosage

1. Different cathode material systems have different demands on the amount of electrolyte,

and the high voltage solid density lithium cobalt acid cathode system battery has the highest capacity and the least electrolyte demand in the same size cell;

The low pressure solid density lithium manganate and lithium iron phosphate positive battery system, the capacity is low, and the electrolyte demand is the largest.

2. The internal resistance of the battery decreases with the increase of the amount of electrolyte,

and the capacity increases with the increase of the amount of electrolyte.

When the amount of electrolyte is too small, the internal resistance of the battery is large and the capacity is low. When the amount of electrolyte reaches a certain amount,

the internal resistance and capacity tend to be stable.

3. The amount of electrolyte has a significant impact on the cycle performance and anti-overcharge performance of the battery.

When the amount of electrolyte is too much or too little,the cycle performance and safety performance are poor.

Because of the strong corrosion of the electrolyte and the precision of the injection, in order to meet special requirements.

For lithium battery enterprises to produce different kinds of lithium batteries such as (EV power soft pack battery, polymer 3C battery, cylindrical 18650 battery,

aluminum shell battery, plastic power battery) and other capacity required by the amount of liquid injection corresponding to different precision ceramic injection pumps.

For example:

A: For example, 3C polymer soft pack battery requires high precision and small injection volume. In particular,

we have specially developed single-head ceramic injection pump with a single-stroke range of 0.1g-1g or double-head

ceramic injection pump suitable for automatic injection machine.

B: If the injection volume of the cylindrical 18650 battery is between 5.7-5.8g,

Ji kerr specializes in the development of single-head ceramic injection pump for max6.5g or double-head

ceramic injection pump and multi-head ceramic injection pump for automatic injection machine.

C. If the one-time injection volume of the power battery is between tens of grams or hundreds of grams,

Jickel has specially developed a large stroke volume of ceramic injection pump, there are multiple specifications,

generally Jickel conventional preparation of one-way max100g,max300g, max500g and other models.

D. Such as micro battery injection in 0.05 grams of micro button battery, Jickel specially developed a one-way max500mg ceramic injection pump.

Note: (The stroke quantity refers to the range from max maximum to min minimum. The stroke quantity of ceramic liquid injection pump is adjustable.)

At present, in view of the high accuracy of the liquid injection volume requirements of lithium batteries,

Ji kerr provides a complete set of solutions for the ceramic liquid injection pump system tailored to the injection machine equipment factory:

cylindrical battery injection machine, EV flexible packaging power battery injection machine, 3C soft pack battery injection machine,

power aluminum shell battery injection machine, power steel shell battery injection machine, button battery injection machine

and other vacuum isobaric liquid injection machine.