News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

common problem

Home > News center > common problem

Approximate viscosity reference table for the most common liquid media

which is only apparent during initial and continuous flow. For example,

a liquid with a high viscosity requires more force to flow than a liquid with a low viscosity. Fluid viscosity is temperature dependent.

2019-06-01

2019-01-16

The cause of bubble in electrolyte and its influence on battery

2019-01-12

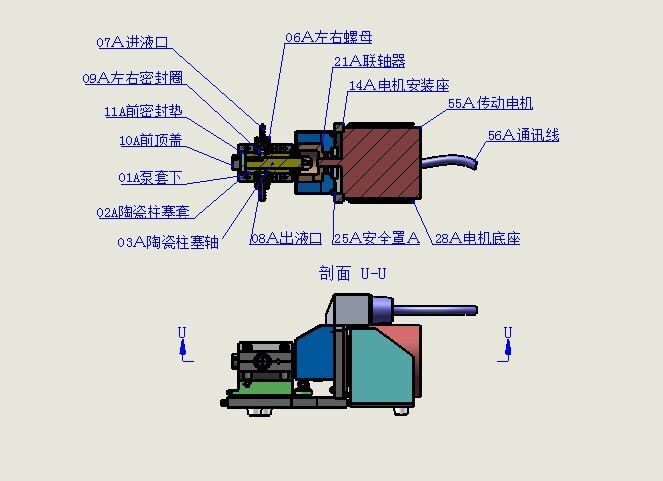

Comparison between pneumatic injection pump and Ji kerr ceramic injection pump

2018-11-21

Safety specification for Ji kerr liquid injection pumps

2. Assign professional trained maintenance personnel to maintain.

3. Maintenance personnel must read and be familiar with this operation instruction before repair or maintenance.

2018-11-13

Ji kerr injection pump daily maintenance failure and treatment

the site can be easily solved, which will help the equipment to maintain good working conditions, improve work efficiency,

and greatly shorten the equipment downtime. The following are some troubleshooting measures that this machine may encounter

2018-11-13

Liquid injection pump stuck pump solution

2018-11-13

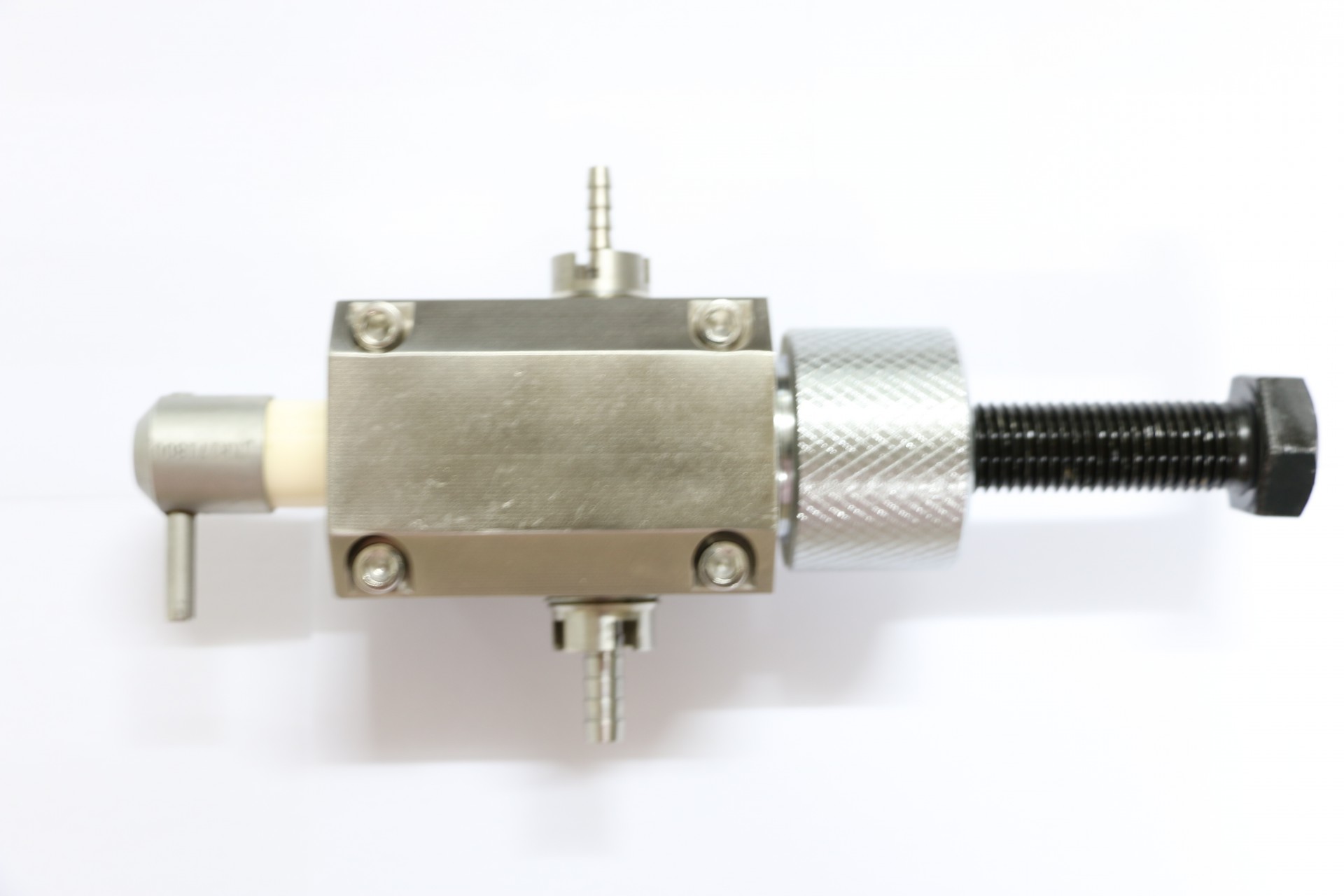

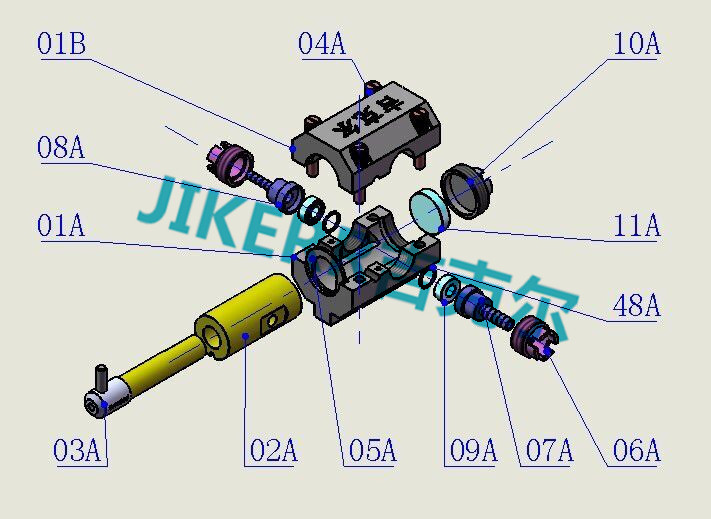

Ji kerr injection pump liquid contact parts

high temperature resistant material. Suitable for use in most harsh environments.

Easy to disassemble and assemble in just 5 minutes.

2018-04-18