News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

common problem

Home > News center > common problem

News center > common problem

Ceramic plunger metering pump fluid injection instability and other failures

Date:2021-08-30 browse:757

Ceramic injection pump is widely used, injection should be targeted at high precision liquid industry,

especially suitable for battery injection machine injection, diagnostic reagent packaging, heat pipe water injection,

COD sulfuric acid packaging injection and other industries.

The working stability and precision of ceramic liquid injection pump determine the qualified rate of product quality. For example,

the accuracy of the injection machine is inaccurate, there are drops, bubbles, and the CPK value fluctuates greatly.

According to our many years of experience now to share with you. I hope it helps.

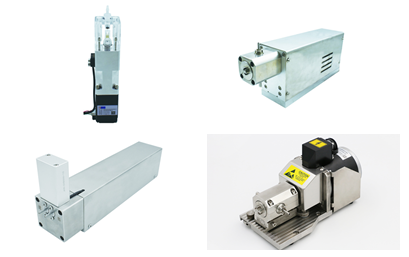

Friends around us commonly used these several ceramic plunger pumps, the current ceramic series of liquid injection pump names are various,

in fact, the most correct name should be called ceramic metering pump (commonly known as liquid injection pump, Haiba pump,

quantitative pump, variable pump, rotary pump, micro pump, electric liquid injection pump, electronic liquid injection pump).

Question 1: Is the amount of liquid injected in the injection pump unstable during injection?

1.1 Check whether the connected pipes of the liquid injection pump are completely sealed and whether they are loose.

1.2 Check whether there are bubbles in the liquid injection process, and use real methods to remove bubbles.

1.3 Check whether the bearing at the connection between the ceramic of the liquid injection pump and the motor is worn.

1.4 Whether the injection needle at the outlet of the injection pump is crystallized or slightly blocked.

1.5 Is the material barrel of the upper computer in a positive or negative pressure state?

Question 2: Does the filling pump have dripping when filling?

2.1 Check whether the needle is blocked.

2.2 The needle of the injection needle should not be larger than the inner diameter of 2.5mm.

2.3 Whether it is in negative pressure state.

2.4 Is the seal of the inlet and outlet pipe of the pump valve old or loose?

Question 3: The injection pump squeaks

3.1 There are crystals before the ceramic plunger and ceramic sleeve at the end of the liquid injection pump.