News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

common problem

Home > News center > common problem

News center > common problem

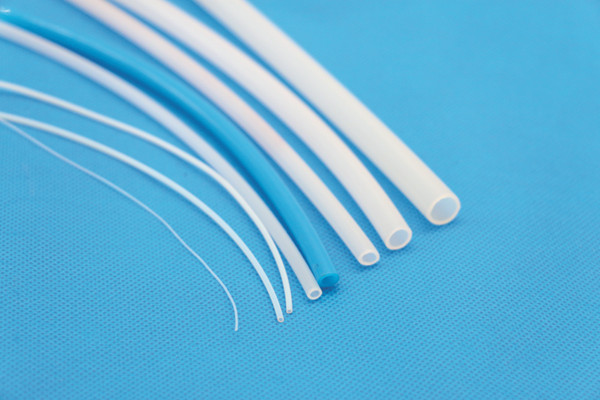

A variety of plastic and polymer material characteristics commonly used or optional for Ji kerr ceramic injection pumps

Date:2021-08-04 browse:291

Ji kerr ceramic metering pumps often use or optional a variety of plastics and polymers, below a brief description of their characteristics.

abbreviation | Full name | Inertia factor |

PTFE | Poly tetra fluoroethylene | 9 |

PEEK | Poly(ether-ether-ketone) | 6 |

EPDM | Ethylene Propylene Diene Monomer | 8 |

FFKM | Perfluoro rubber | 9 |

POM | Polyformaldehyde | 3 |

PTFE is a polymer compound made of tetrafluoroethylene by polymerization, with acid and alkali resistance, resistance to various organic solvents,

almost insoluble in all solvents. At the same time, it has sealing, high lubrication non-viscosity, electrical insulation and good aging resistance,

excellent temperature resistance. Its low hardness and easy cold flow make it a good choice for ribbon particle applications. Teflon itself is not toxic to humans.

PEEK is a special engineering plastic with excellent performance. Compared with other special engineering plastics, it has more significant advantages,

such as radiation resistance, stable insulation, hydrolysis resistance, pressure resistance, corrosion resistance,

and the mechanical parts made of composite materials have self-lubricating effects. Temperature resistance, good thermal stability,

ultra-high heat resistance (better than PPS), HDT above 315 degrees Celsius, UL continuous use temperature is 260 degrees Celsius.

EPDM- the synthesis of ethylene and propylene as the main raw materials, aging resistance, electrical insulation properties and ozone resistance outstanding.

The modified products provide many varieties and grades for the wide application of ethylene propylene rubber, and also obtain great improvement in performance.

FFKM- chemically inert material similar to PTFE, has excellent high temperature resistance, chemical corrosion resistance,

but also has the elasticity of rubber, but also has excellent air tightness, high cleanliness and plasma resistance.

POM- is a kind of white or black plastic particles, with high hardness, high steel, high wear characteristics,

and good insulation resistance and not affected by humidity, is suitable for non-corrosive chemicals material.