Product center

- Precision ceramic piston pump valve series

- Liquid nitrogen point liquid frozen beads series

- Diagnostic reagent drop package series

- Ceramic plunger pipette pump series

- Micro upgrade ceramic metering pump series

- Millilitre ceramic injection pump series

- Intelligent single head metering pump series

- Intelligent multi-head metering pump series

- Ceramic constant current metering pump series

- Large flow rotary valve metering pump series

- High viscosity material variable pump series

- Stainless steel pressure container series

- Ji kerr computer controller series

- Injection pump valve auxiliary accessories series

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

Intelligent multi-head metering pump series

Home > Product center > Intelligent multi-head metering pump series

Product center > Intelligent multi-head metering pump series

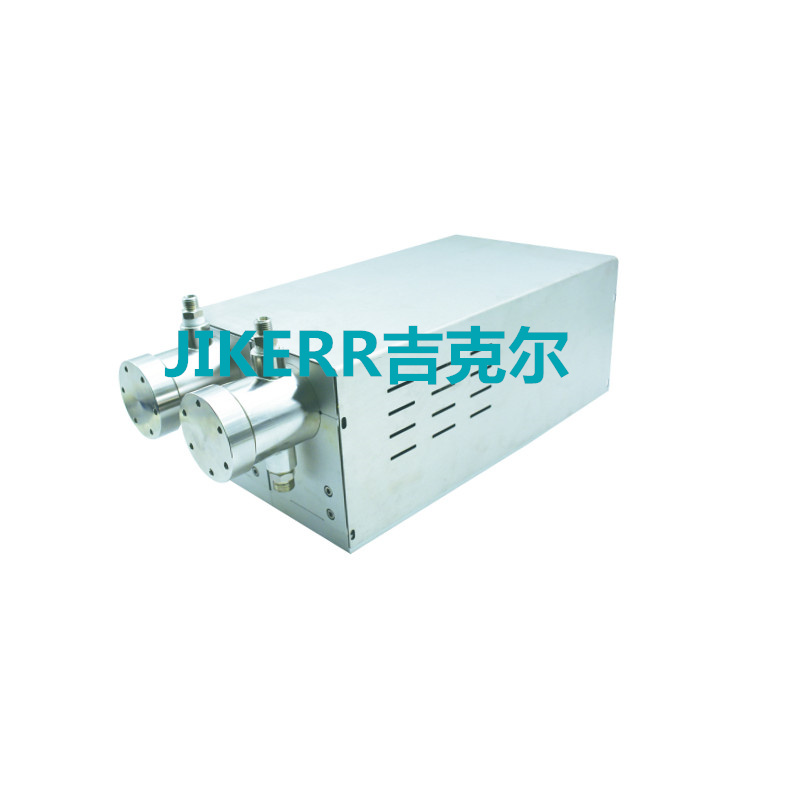

Double head intelligent metering pump series

l Compact structure, small size, high precision, corrosion resistance and high temperature resistance.

l The 2 heads are easy to disassemble and install and can be cleaned online by switching the valve to the forward and reverse directions.

l It can be sterilized by negative pressure, high temperature and steam.

l Precision wire motor drive, high performance, long service life, high strength and repeatable operation.

l Digital touch screen mediates measurement capacity.

l No quick-wear parts, zero maintenance and repair costs.

l Anti-chemical reaction prevention is compatible with most fluids.

Telephone:0769-83328418

Message feedbackDetailed introduction

Widely used for:Precise quantity filling of liquids such as biological agents, pharmaceuticals, batteries, CVs, heat pipes, liquid agents, perfumes, etc.

Product performance:

l Compact structure, small size, high precision, corrosion resistance and high temperature resistance.

l The 2 heads are easy to disassemble and install and can be cleaned online by switching the valve to the forward and reverse directions.

l It can be sterilized by negative pressure, high temperature and steam.

l Precision wire motor drive, high performance, long service life, high strength and repeatable operation.

l Digital touch screen mediates measurement capacity.

l No quick-wear parts, zero maintenance and repair costs.

l Anti-chemical reaction prevention is compatible with most fluids.

Technical Parameters

Specification & Model | JKR-ZNX2-M500µl | JKR-ZNX2-M1500µl | JKR-ZNX2-M3500µl | JKR-ZNX2-M6500µl | JKR-ZNX2-M10ml |

Plunger material | Alumina / zirconia / silicon nitride / sapphire (optional) | ||||

Valve direction switching | Stepper motor | ||||

Driving mode | Precision screw motor / servo (optional) | ||||

Stroke speed | 1-200r / min (preparation and selection) | ||||

Adjustment mode | Digital screen touch screen smart adjustment | ||||

No. of pump heads | 2 | ||||

Single stroke range | 3-500µL | 5-1500µL | 20-3500µL | 50-6500µL | 0.1-10ml |

Stroke accuracy | ±0.3‰ | ±0.4‰ | ±5‰ | ±5‰ | ±5‰ |

Liquid inlet pipe | Φ2.5×4mm | Φ4×6mm | Φ6×8mm | Φ6×8mm | Φ6×8mm |

Outlet pipe | Φ1.0×1.6mm | Φ2.5×4mm | Φ4×6mm | Φ4×6mm | Φ4×6mm |

Communication interface | RS23 2(485 optional), I/O, CC TRIG, AUX OUT | ||||

Power supply | 220V/50HZA or 120V/60HZ (optional) | ||||

Work environment | Use temperature and humidity 5-40℃, below 85%RH | ||||