News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

trade news

Home > News center > trade news

News center > trade news

Heat pipe and its working principle are introduced

Date:2019-12-27 browse:1359

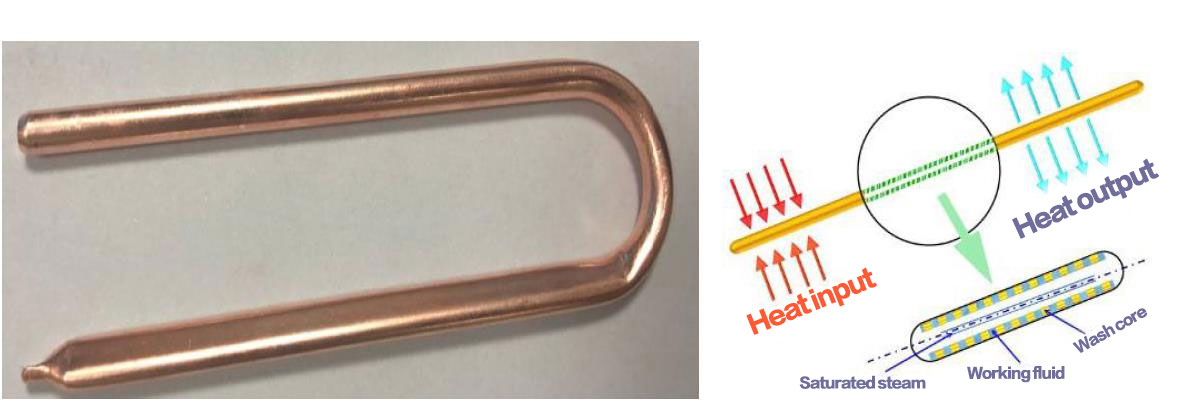

1. heat pipe (heat pipe), is the use of evaporation refrigeration, so that the temperature difference between the two ends of the heat pipe is very large,

so that the heat is quickly transmitted. The general heat pipe is composed of a tube shell, a liquid suction core and an end cover.

The interior is pumped into a negative pressure state and filled with the appropriate liquid, which has a low boiling point and is easy to volatilize.

● Heat pipe, is a heat transfer element with extremely high thermal conductivity,

it transfers heat through the evaporation and condensation of liquid in a fully enclosed vacuum tube!

● Its conduction does not need to use any machinery, electricity, fuel, only need to exceed its own starting temperature,

and form a temperature difference can be conducted! The heat pipe is not affected by gravity and the direction of use.

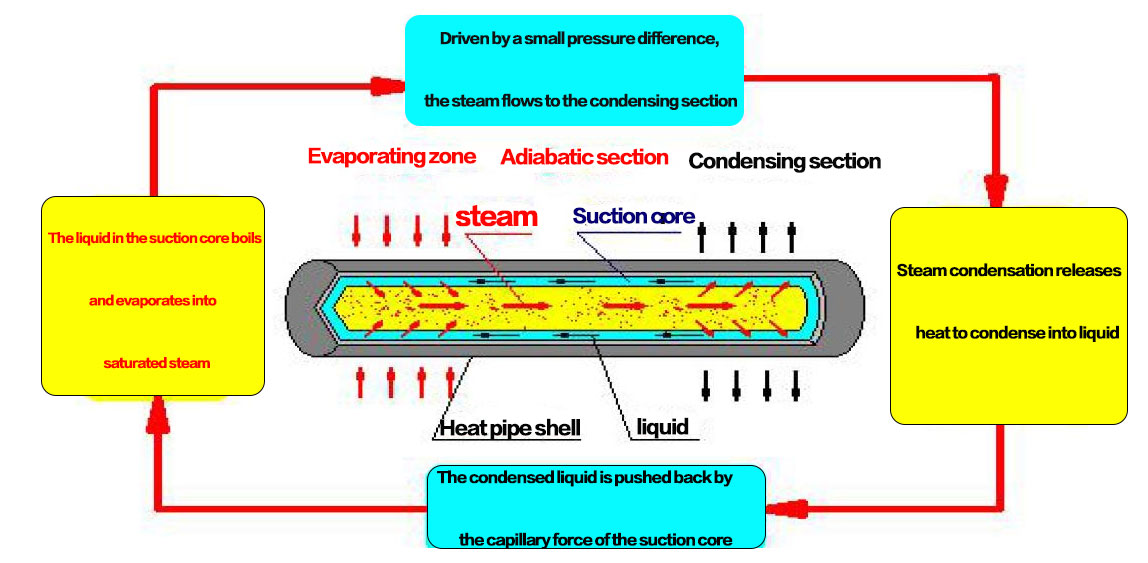

2. Heat pipe operation principle:

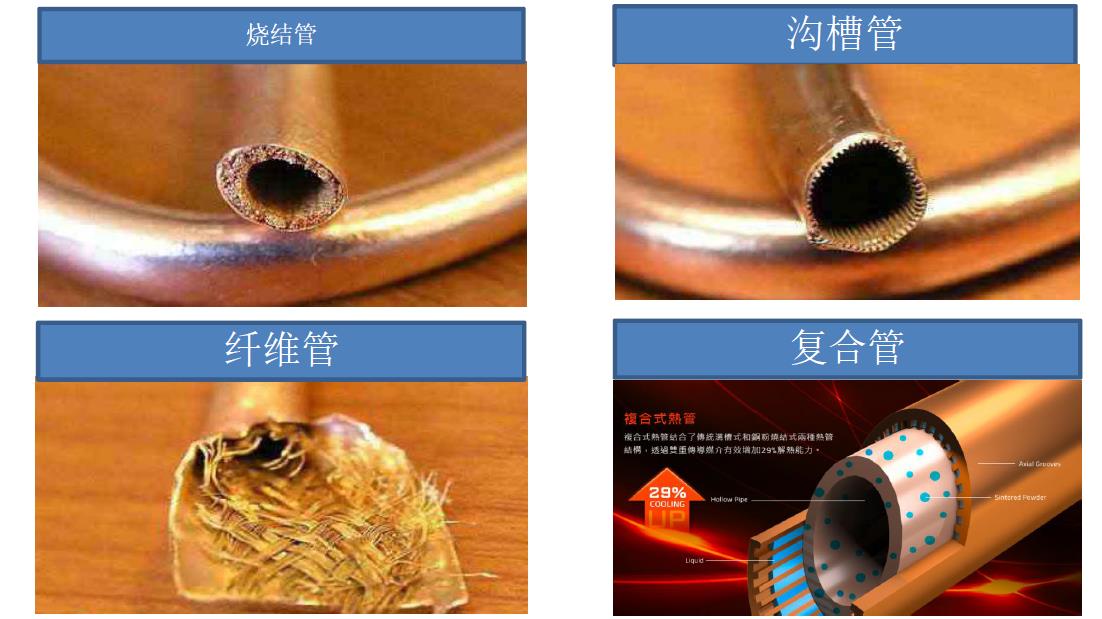

3. Heat pipe structure: 1. Closed container. 2. Capillary structure. 3. Actuating fluid.

Application of heat pipe in heat dissipation of notebook computer

With the continuous improvement of laptop performance, heat dissipation has become a key factor,

which directly affects the stable operation of the system. Due to the limitation of space and power consumption,

heat pipes with excellent heat dissipation performance are widely used in laptop cooling systems.

Heat pipe heat dissipation is used in laptop intelligent temperature control system,

which changes the traditional noise problem caused by simply relying on increasing air volume heat dissipation;

Therefore, the heat pipe heat dissipation can well meet the heat dissipation requirements of the laptop CPU. Usually,

the laptop computer uses a small fan, heat FIN fin, heat conduction tube combined with heat dissipation,

heat pipe structure can be sintered heat pipe flattening and laminating, or the use of composite heat pipe flattening and laminating.

Application of heat pipe in heat dissipation of computer CPU

The heat dissipation of CPU heat pipe is divided into two types: downpressure type and side blowing type.

The heat pipe is upgraded in the traditional air-cooled cooling platform, and the heat pipe is introduced into the air cooling,

thus improving the heat conduction efficiency of the heat sink, and the efficiency of the CPU heat sink is doubled by improving the heat sink.

Lower pressure radiator

The lower heat sink is similar in appearance to the original heat sink, but is more efficient with the introduction of heat pipes.

The downward pressure heat dissipation fan directly blows the heat sink down and the air volume can directly reach the CPU and other components of the surrounding motherboard. The advantage of this heat dissipation method is that it can cool the CPU at the same time,

the fan can bring certain heat dissipation effect to the motherboard, north bridge and memory at the same time.

Advantages: small size, suitable for small chassis installation; Can bring heat dissipation effect to the motherboard.

Side-blown radiator

Side-blown heat dissipation is conducted through the tower structure heat sink and heat conduction tube,

and the fan side blows heat dissipation fin for heat dissipation, because the tower heat sink is used,

the heat dissipation area is larger, and the auxiliary pipe is more obvious heat dissipation efficiency.

And the side-blown fan and the chassis fan frame constitute an air duct system,

which can effectively discharge the heat generated by the CPU. Benefits: CPU heat dissipation effect is more obvious,

and the fan is connected to discharge hot air.

Heat pipes are used to dissipate heat from memory modules

Memory overclocking can improve the memory storage performance, speed up the memory computing and processing storage speed,

to improve the computer running speed has a certain effect, but to run in the frequency supported by the computer motherboard,

overclocking is too high will lead to memory heat, the temperature rises sharply resulting in goldfinger or chip damage,

and may burn the motherboard, this time a good heat sink, It plays a very important role in the stable running of memory and ensuring the service life.

The heat sink of the memory bar can relatively ensure the stable operation and prolong the life of the memory bar.

The heat pipe and buckle are used to fully fit the heat source, and the heat absorption efficiency is effectively improved.

The heat is transferred to the FIN FIN through the heat dissipation,

which effectively reduces the memory temperature and ensures the normal operation of the constant temperature.

The heat pipe adopts sintered heat pipe, and the absorbing end is flattened by 3mm.

Sintered heat pipe single power consumption of 30-35W, combined with the heat sink,

can effectively improve the heat dissipation effect.

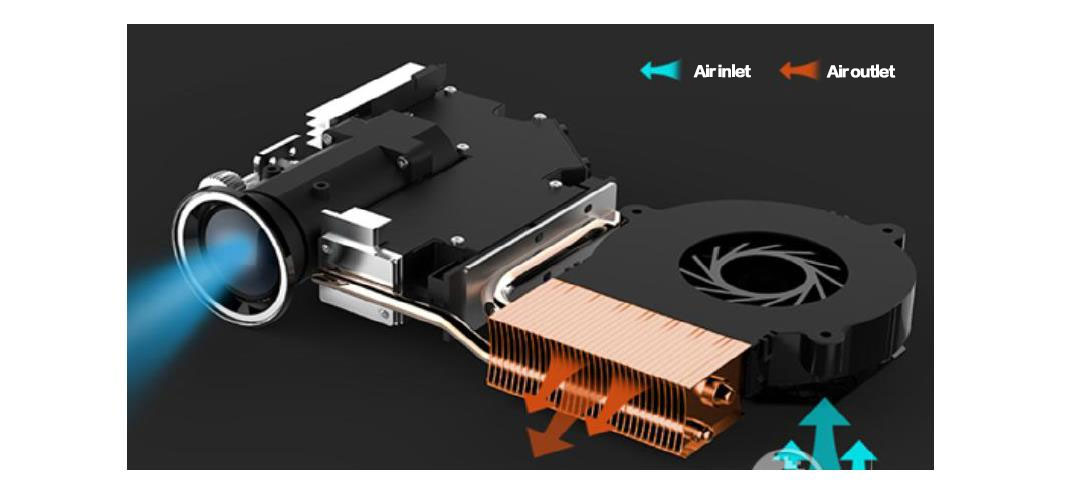

Application of heat pipe in heat dissipation of projector

With the popularity of projector applications, the optical part is the core of imaging display in the entire projector structure,

among which the light bulb and liquid crystal plate and its accessory optical devices are the main components that generate heat and are easy to be damaged by heat.

If you do not take measures to quickly remove the heat accumulated in the projector, it may damage the optical components inside the projector,

in order to ensure the safety of the use of the projector, it is necessary to take measures to protect the projector from high temperature heat. At present,

many projectors sold on the market are heat dissipated by installing heat pipes + heat sinks + fan groups inside the projector to heat the optical imaging system inside

the projector and the heat generated by the power supply part of the projector; In this way, when the projector works,

under the action of the heat pipe guided heat transfer and heat dissipation fan, its internal will be in a state of thermal balance.

Its working principle: the heat pipe first conducts the heat generated by the light bulb and the liquid crystal plate and its accessory optical devices to the FIN fin fin,

and then the heat is blown away by the small fan, and the cycle work makes the internal heat balance to avoid excessive temperature resulting in damage to the optical devices.

Application of heat pipe in heat dissipation of integrated machine

All-in-one computers have inherent advantages, fashionable appearance, thin and delicate, space saving, energy saving and so on. However,

due to the high degree of integration, the all-in-one computer also brings a high degree of heat concentration; At the same time,

the heat dissipation does affect the performance and life of the various components of the all-in-one computer.

The heat dissipation of an all-in-one computer mainly depends on two factors: the air duct design + cooling module as shown in the figure,

the heat pipe + fin + turbo-cooling fan is combined to form a radiator, and the heat pipe guides the CPU heat to the fin position

According to the heat level, the turbine cooling fan intelligent speed regulation, suction cold air and blow to the fin position,

after the turbine cooling fan control the internal heat of the machine will be reduced, the heat through the special design channel convection heat dissipation outside the machine.

Application of heat pipe in industrial and mining lamps

The heat pipe is directly in contact with the aluminum substrate, the heat emitted by the light source is quickly imported to the outside,

and the heat dissipation of the metal stamping sheet can be realized, and the heat dissipation solution of the 400W and above industrial and mining lamps can be achieved,

and the weight is light.

Combined mining lamp, built-in 8 heat pipes; Eight heat pipes export heat from the light source to the radiator, achieving light weight,

rapid heat conduction, and efficient heat dissipation.

Application of heat pipe in heat dissipation of graphics card

As the core operating frequency of the graphics card and the operating frequency of the video memory continue to rise,

the heat output of the graphics card chip is also rapidly increasing. Heat pipe heat transfer has the following advantages:

light weight and simple structure; The temperature distribution is average, which can be used for equalizing temperature or isothermal action;

The heat transmission quantity is large and the heat transmission distance is long. No active components, itself does not consume electricity;

Can be used in the environment without gravity field; There is no restriction on the direction of heat transfer,

the evaporating end and the condensing end can be interchanged. Easy to process to change the direction of heat transfer;

Durable, long life, reliable, easy storage and storage. Heat pipe thermal conductivity process has a high heat conduction performance,

compared with metal, unit mass heat pipe can transfer several orders of magnitude more heat,

and has excellent isothermal and thermal switching performance, especially suitable for high-precision heat dissipation environment.

Application of heat pipe in power supply

The 600W power supply of heat pipe +12CM fan,

coupled with heat pipe cooling and extremely low speed 12CM fan makes it excellent in heat dissipation and quiet performance.

Heat pipe + air-cooled dual heat dissipation means that the heat generated by

the rectification of the secondary side rectifier tube is transferred to

the connected metal fin (the metal fin is close to the heat dissipation hole of the power supply) through the heat pipe and

the secondary side heat sink inside the power supply on the basis of the above-mentioned various air cooled heat dissipation.

Under the action of air cooling, the hot air is quickly discharged to the outside of the power supply.

The effect of 2 heat dissipation is achieved. This design dissipates heat quickly and makes little noise.