News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

trade news

Home > News center > trade news

News center > trade news

The basic principle and control method of ceramic metering pump are analyzed

Date:2019-01-04 browse:745

summarize

As the ideal metering equipment for precision fluid metering, injection, addition, packaging, drip, sampling,

Ji kerr ceramic metering pump has been widely used in battery injection, biologics, micro electronics, food and beverage and chemical industry and other fields.

In the high standard and high requirements of the production process process, it undertakes the task of adding and conveying the fluid medium with high precision,

strong corrosion and toxicity. After years of practical application and technical improvement, ceramic metering pump has now entered its high-speed growth period.

Now, due to the new material ceramic technology from raw material - sintering - precision processing continues to stabilize and mature.

The performance, quality and cost of the ceramic metering pump have been dramatically changed,

and the unique precision and stability of the ceramic metering pump can almost complete the chemical protection requirements of most liquid media under the power drive.

With the general improvement of China's industrial intelligent automation production requirements, as a domestic ceramic metering pump R & D and sales enterprises,

with skilled and experienced R & D personnel. The safety, controllability and intelligence of ceramic metering pump are becoming increasingly important.

principle

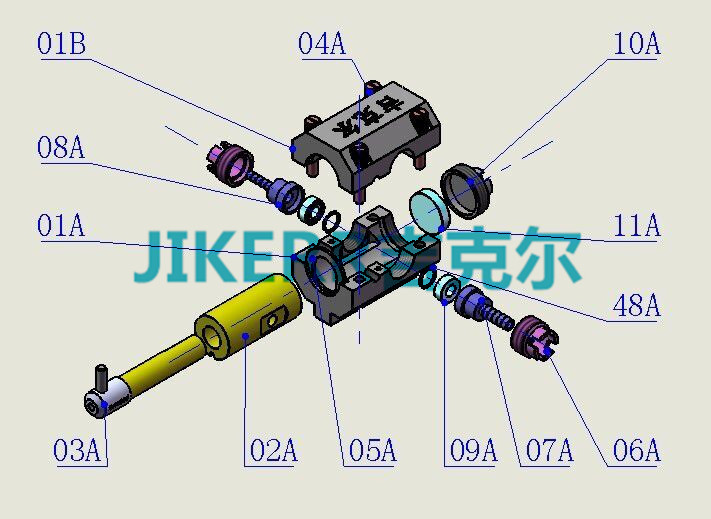

Ceramic metering pump is mainly composed of three important mechanisms: stepper motor drive, ceramic valve body and regulating controller.

Due to the different power drive methods, there are two types of rotary reciprocating and linear push-pull.

Rotary reciprocation by the stepper motor power drive device to drive the ceramic rod reciprocating push and pull rotation (ceramic piston) to achieve reciprocating piston movement,

complete the fluid transport to the desired destination.

The precision ceramic valve chamber ensures each suction and discharge volume, thus realizing the precise measurement of the transported medium.

The linear push-pull type is telescopic movement by the stepper motor, and under the coordination of the check valve,

the fluid is pulled in and pushed to achieve the goal of precision measurement.

Rotary reciprocating ceramic metering pump

Rotary reciprocating ceramic metering pump is very convenient for maintenance and maintenance because of its simple structure,

and it basically only takes 2-3 minutes to disassemble and assemble, and is widely used in the field of battery injection and biological reagents.

The high viscosity medium is subject to many restrictions in the high pressure working environment.

Linear push-pull ceramic metering pump

The linear push-pull ceramic metering pump has a high degree of intelligence, and there is no need to manually adjust the liquid injection amount,

so as to achieve intelligence and automation. Compared with rotary reciprocating, the structure is relatively complex and difficult to disassemble,

and the pump body consists of more components.

Controls

The metering pump controller is equipped with the upper computer R232 communication port,

which can realize the monitoring and control of the metering pump by the upper computer. At the same time, there are switching input and output,

alarm, time feedback, complete feedback signal.

Rotary reciprocating control

Each stroke chamber of the metering pump determines its metering capacity. The flow rate of the output medium of the pump depends on the stroke length,

the volume of the ceramic chamber and the number of strokes. In the case of determining the metering medium and working pressure,

the output of the metering pump can be adjusted by manually adjusting the stroke length (that is, the Angle) and setting the stepping speed and rotation direction through

the man-machine interface.

Linear push-pull control

The same linear push-pull ceramic metering pump each stroke chamber, determines the size of its metering capacity.

The flow rate of the output medium of the pump depends on the stroke length, the volume of the ceramic chamber and the number of strokes.

When the measuring medium and working pressure are determined, the output of the metering pump can be adjusted by adjusting the stroke length.

Although both stroke length and stroke compensation can be used as adjustment variables, in engineering applications,

stroke length is generally regarded as a coarse adjustment variable, and stroke compensation is a fine adjustment variable: adjust the stroke length to a certain value,

and then change its compensation to achieve fine adjustment and increase the flexibility of adjustment.

In relatively simple applications, the stroke length can also be set manually, with only stroke frequency as the regulating variable, thus simplifying system configuration.