Product center

- Precision ceramic piston pump valve series

- Liquid nitrogen point liquid frozen beads series

- Diagnostic reagent drop package series

- Ceramic plunger pipette pump series

- Micro upgrade ceramic metering pump series

- Millilitre ceramic injection pump series

- Intelligent single head metering pump series

- Intelligent multi-head metering pump series

- Ceramic constant current metering pump series

- Large flow rotary valve metering pump series

- High viscosity material variable pump series

- Stainless steel pressure container series

- Ji kerr computer controller series

- Injection pump valve auxiliary accessories series

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

Precision ceramic piston pump valve series

Home > Product center > Precision ceramic piston pump valve series

Product center > Precision ceramic piston pump valve series

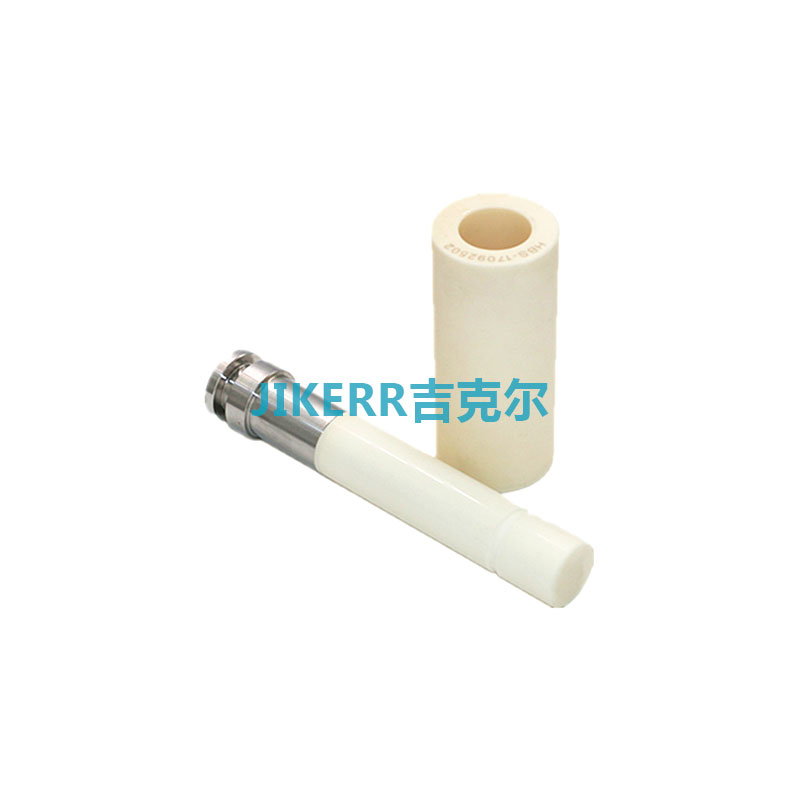

Vacuum filling ceramic cup

Performance Features:

l Anti-chemical reaction widely used in transportation of most chemical media.

l Precisely matched grinding process, matching clearance ≤0.003mm.

l Resistant to acid and alkali corrosion.

l Wear resistance—millions of operations have almost no wear and long service life.

l High intensity and repeatable operation.

l The material is dense, and the filling precision is high.

l Can completely replace imported ceramics.

Telephone:0769-83328418

Message feedbackPrevious:Ceramic rotary valve series

Detailed introduction

Application fields: Suitable for vacuum injection of lithium battery injection machines or vacuum injections of other fluids;

Performance Features:

l Anti-chemical reaction widely used in transportation of most chemical media.

l Precisely matched grinding process, matching clearance ≤0.003mm.

l Resistant to acid and alkali corrosion.

l Wear resistance—millions of operations have almost no wear and long service life.

l High intensity and repeatable operation.

l The material is dense, and the filling precision is high.

l Can completely replace imported ceramics.

Technical Parameters

Specification & Model | Material | Diameter of pump core | Matching accuracy | Measurement accuracy |

JKR-TCF03 | Alumina / Zirconium | ∅3mm | ≤3μm | ≤0.5% |

JKR-TCF06 | Alumina / Zirconium | ∅6mm | ≤3μm | ≤0.5% |

JKR-TCF08 | Alumina / Zirconium | ∅8mm | ≤3μm | ≤0.5% |

JKR-TCF10 | Alumina / Zirconium | ∅10mm | ≤3μm | ≤0.5% |

JKR-TCF13 | Alumina / Zirconium | ∅13mm | ≤3μm | ≤0.5% |

JKR-TCF14 | Alumina / Zirconium | ∅14mm | ≤3μm | ≤0.5% |

JKR-TCF16 | Alumina / Zirconium | ∅16mm | ≤3μm | ≤0.5% |

JKR-TCF18 | Alumina / Zirconium | ∅18mm | ≤3μm | ≤0.5% |

JKR-TCF20 | Alumina / Zirconium | ∅20mm | ≤3μm | ≤0.5% |

JKR-TCF25 | Alumina / Zirconium | ∅25mm | ≤3μm | ≤0.5% |

JKR-TCF30 | Alumina / Zirconium | ∅30mm | ≤3μm | ≤0.5% |

JKR-TCF35 | Alumina / Zirconium | ∅35mm | ≤3μm | ≤0.5% |

JKR-TCF40 | Alumina / Zirconium | ∅40mm | ≤3μm | ≤0.5% |

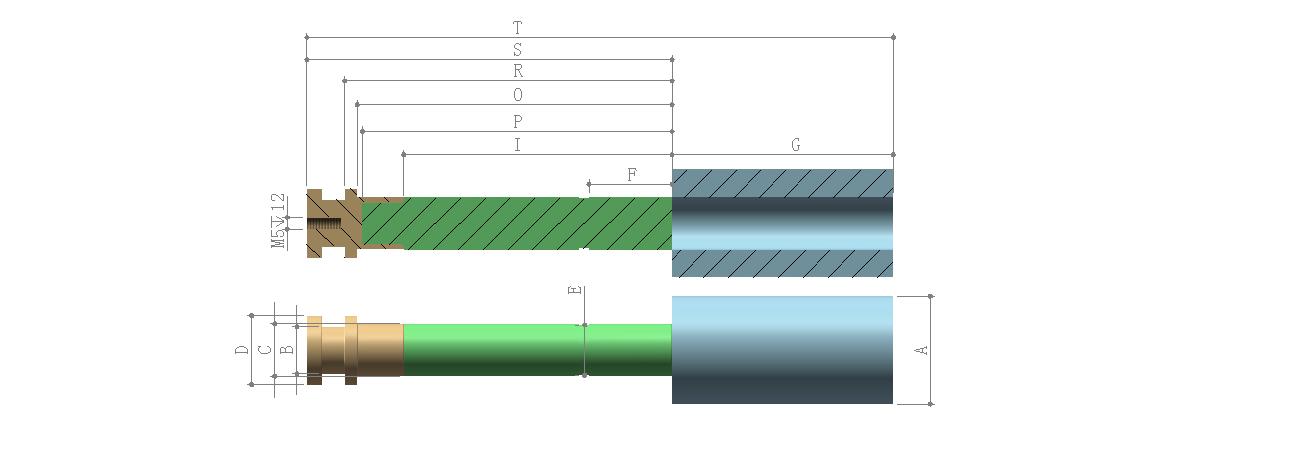

External dimensions

Note: Ji Kerr can customize or replace any domestic or foreign brands for you. The shape and size can be customized according to the needs of the design and processing.