Application case

- Biomedical case

- Battery industry case

- Chemical industry case

- Food industry case

- Daily chemical industry case

- Electronics industry case

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

Battery industry case

Home > Application case > Battery industry case

Application case > Battery industry case

18650 cylindrical battery divided into multiple phases of liquid injection case

Date:2018-11-23 browse:950

Steel shell cylindrical lithium-ion battery is a very critical process in the liquid injection process, and the injection precision control of electrolyte

is very important. When cylindrical lithium-ion battery is injected, the first electrolyte can not be injected more, which will lead to leakage when

the battery is sealed or cause the safety valve to burst when charging. The second liquid injection amount is too low will cause the battery internal

resistance to increase, easy to reach, may cause fire and explosion.

At present, the injection of cylindrical batteries is still a bottleneck, due to the influence of the positive and negative electrode sheets of the battery

through the roller surface density and the tightness of the cell when winding, if 5.6 grams is injected at the time of injection, the electrolyte is difficult

to quickly penetrate into the electrode sheet due to the limited space volume capacity of the battery housing. With the increasing chemical composition

of positive and negative electrode plates, diaphragms, and electrolytes, the battery capacity is pursued more and more. Most of the domestic battery

manufacturing enterprises and injection machine equipment enterprises to develop a new and simple production of high tempo, but also low cost of

cylindrical battery multi-stage injection machine.

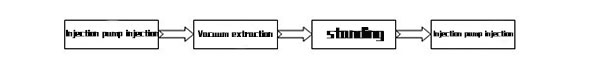

The basic principle of the multi-stage injection machine is to adopt the step injection test method. If our injection volume is 5.6 grams,

we will take a split injection. After 1.6 grams of electrolyte is injected into the first injection pump, 1.5 grams of electrolyte is injected into

the second injection pump, and static infiltration is completed. After static infiltration is completed, 1 gram of electrolyte is injected into

the third injection pump, and 1 gram of electrolyte is injected into the fourth injection pump, and static infiltration is completed.

The fifth injection pump injected 0.5 grams of electrolyte, and the final injection of battery was completed after the completion of static infiltration.

Although the injection bottleneck can not be completely solved through this process, the injection accuracy is fully guaranteed under the cooperation

of Ji kerr injection pump, and the phenomenon of electrolyte overinjection or underinjection will no longer occur. At the same time, the production

capacity has also been a leap, on the basis of the original to improve the production capacity of at least 2.

Ji kerr injection pump application site