News center

Contact us

Dongguan Ji kerr automation Technology Co., LTD

Telephone:0769-83328418

Fax:0769-83328428

Email:dgjikeer@126.com

Address:80 Luxi Road, Xixi Village, Liaobu Town, Dongguan City, Guangdong Province

Company news

Home > News center > Company news

News center > Company news

Ji kerr electrolyte bubble removal solution for lithium battery injection

Date:2018-11-15 browse:962

When the lithium battery is injected, the electrolyte needs to be injected into the cell, and the electrolyte contains metal ions,

which conduct electric energy. In the common battery production process, the electrolyte will inevitably dissolve part of the gas during production,

transportation and use. In the battery injection process, bubbles will be generated in the injection pipeline due to the sudden change of air pressure,

resulting in the phenomenon of dripping and unstable injection accuracy during the injection, resulting in the decline of product quality. Therefore,

we have developed a reliable and practical solution of electrolyte vacuum stirring to remove bubbles:

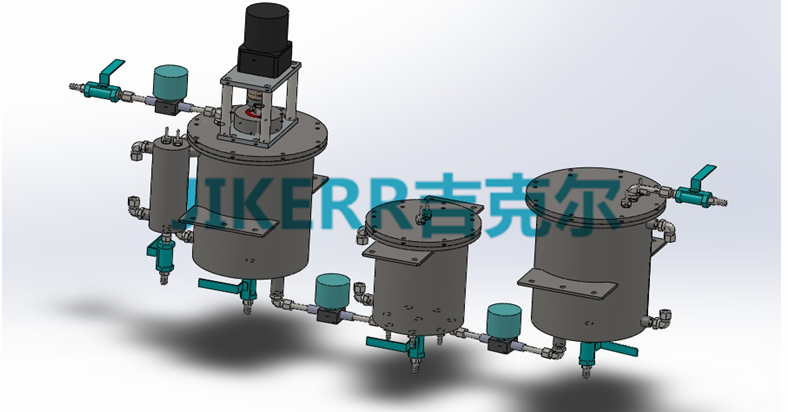

it is mainly used to remove the bubbles generated by the electrolyte in the process of nitrogen pressure transport through the electrolyte mother tank during liquid injection,

and the internal tiny bubbles are physically broken by mechanical stirring, and the bubbles are removed by vacuum-pumping.

Ensure that there are no bubbles in the liquid injection connection pipeline,

and solve the bubbles generated by the electrolyte in the liquid injection connection pipeline during the operation of the equipment,

resulting in dripping and unstable injection precision when the liquid injection pump is injected.

At the same time, the electrolyte vacuum stirring bubble removal system is also equipped with a liquid injection pump and injection needle automatic cleaning device,

which can be set by touch screen to automatically clean the liquid injection pump and injection needle with DMC liquid in the cleaning device bucket,

and the cleaned DMC can be automatically recycled into the waste liquid collection bucket through the liquid receiving tank.

The solution of electrolyte vacuum stirring to remove bubbles mainly includes the functions of electrolyte vacuum stirring to remove bubbles,

cleaning system controlled by PLC, man-machine interface, automatic filling of electrolyte, automatic safety protection of liquid level excess, etc.

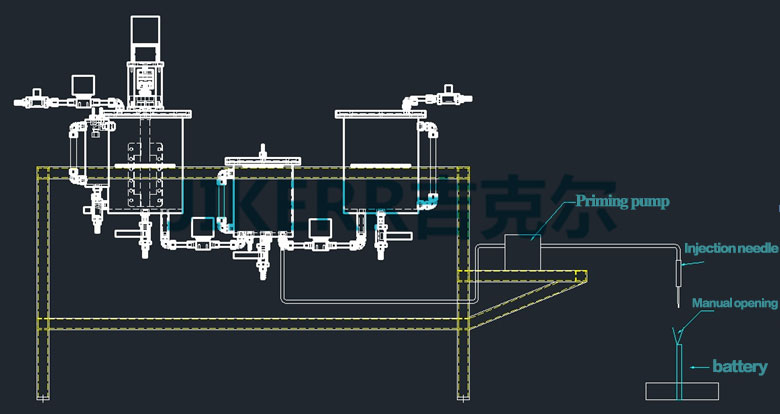

Electrolyte vacuum stirring solution for removing bubbles when filling the liquid diagram is as follows: